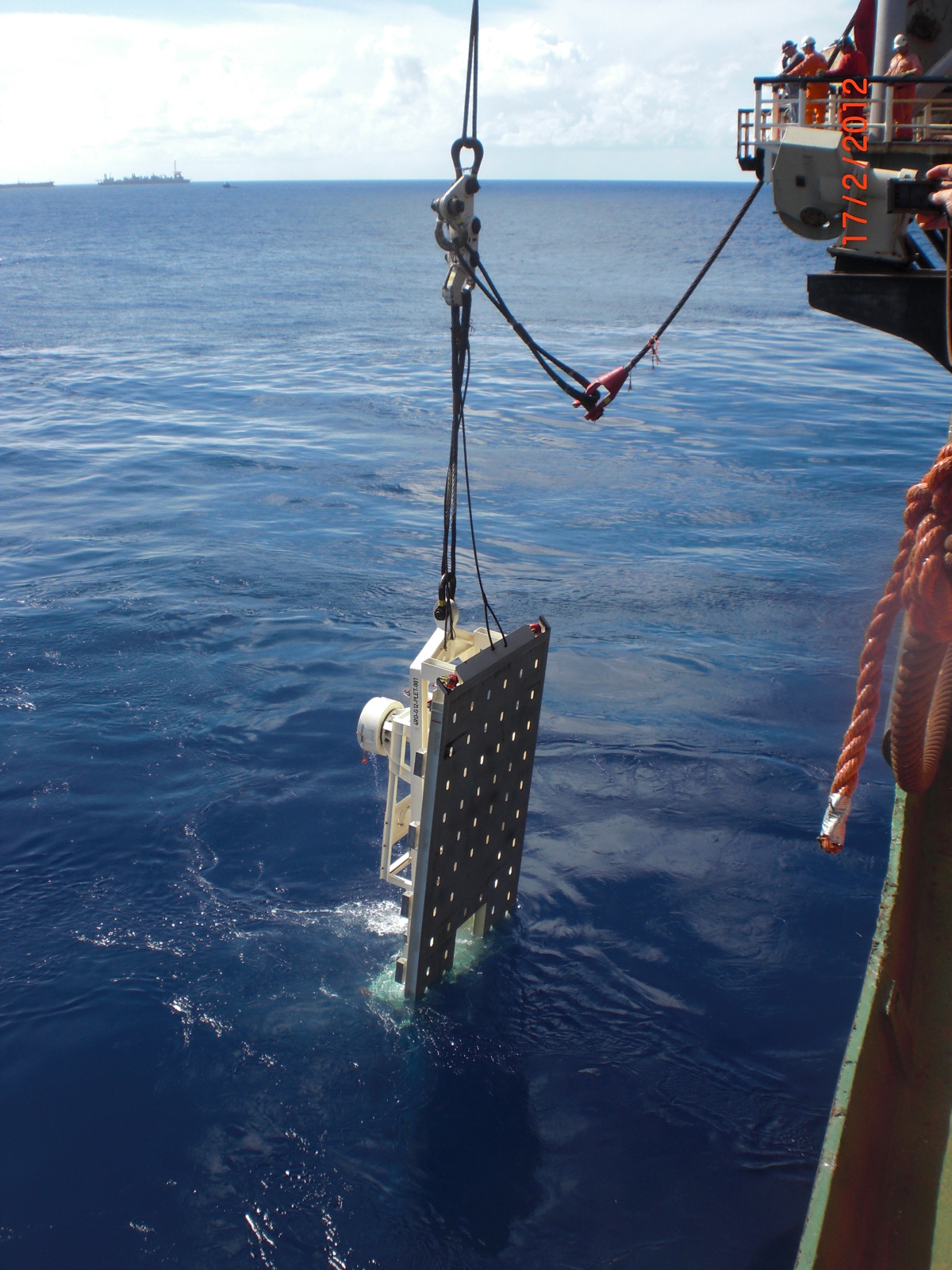

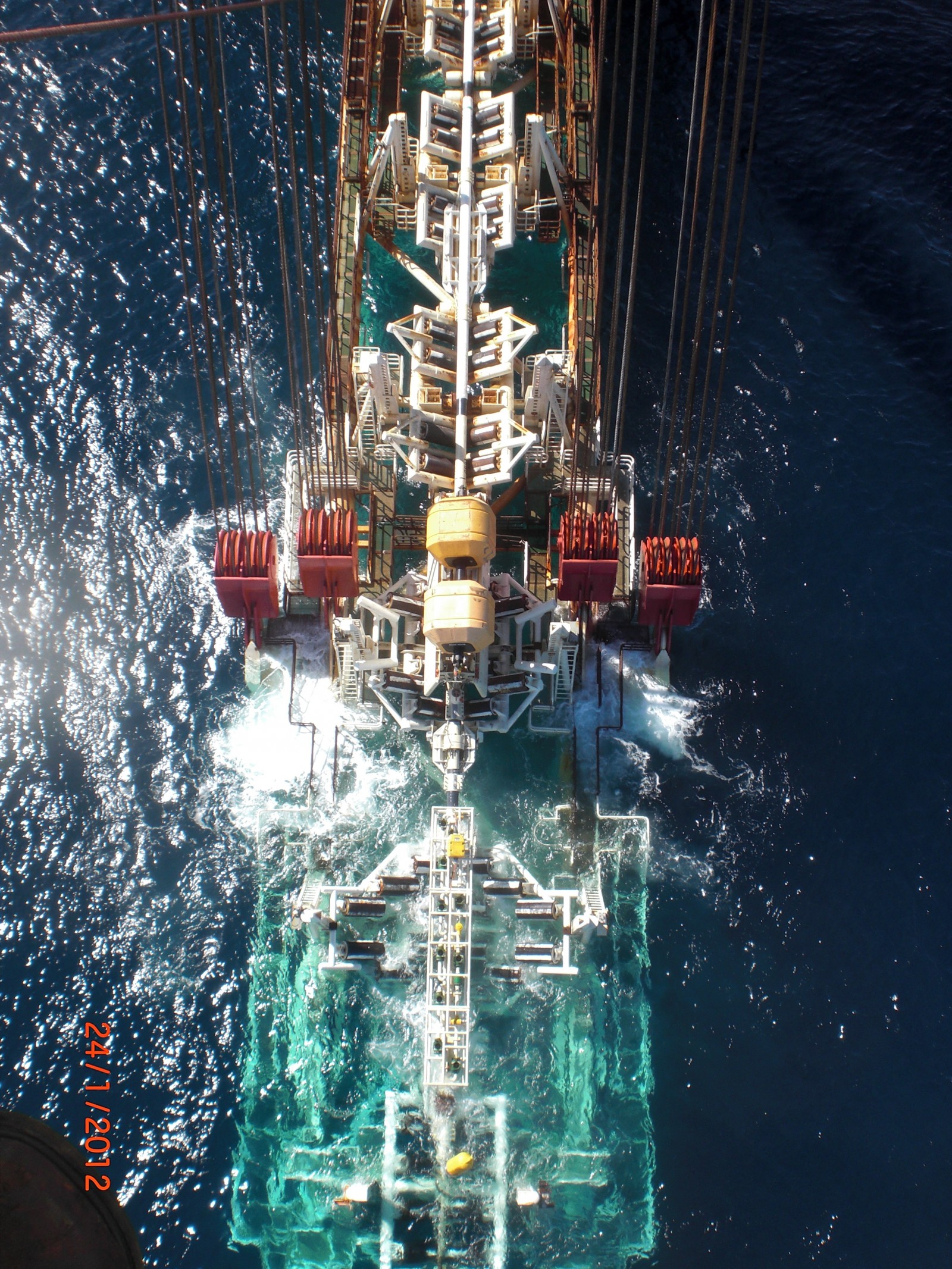

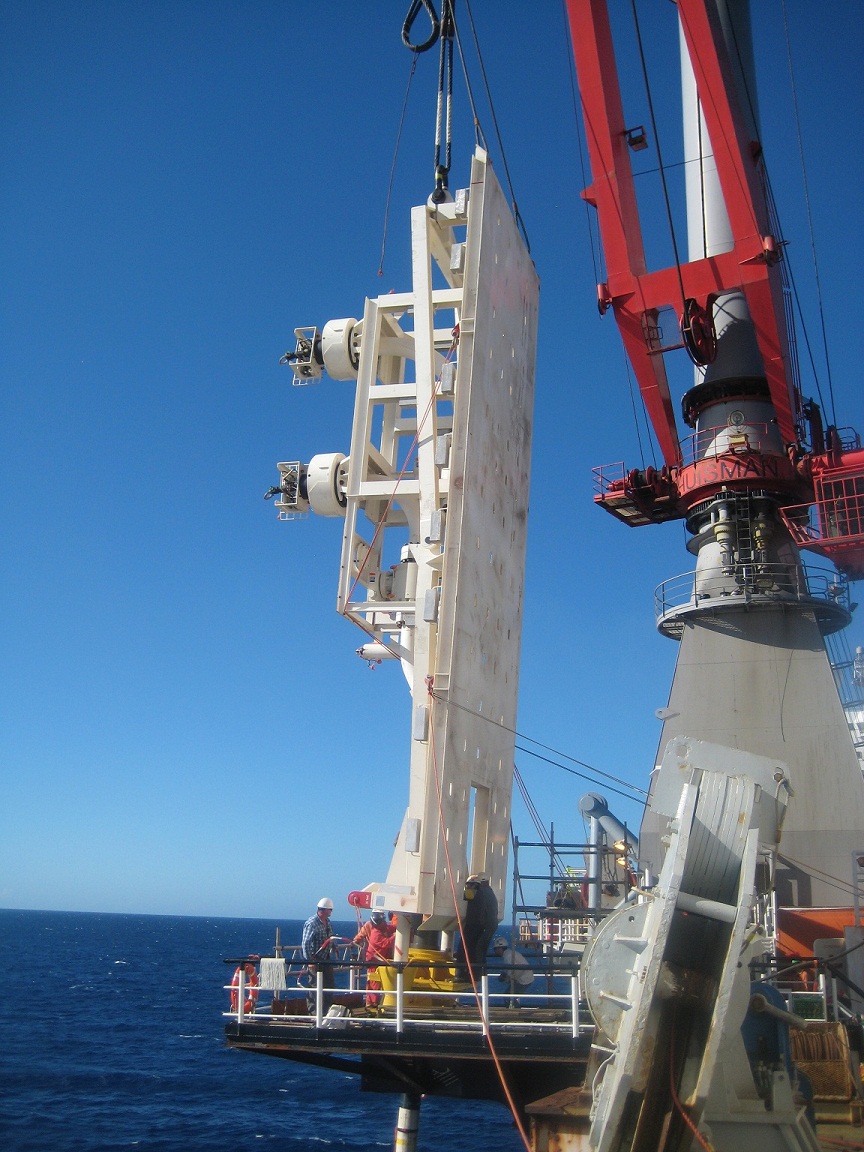

General information

| Client | Petróleo Brasileiro S/A (Petrobras) |

| Project | Profundo P62 |

| Year | 2012 |

| Location | Offshore Brazil (Campos Basin Rio de Janeiro & Espírito Santo) |

| Vessels | Solitaire |

| Max. water depth | 1453 m (4795 ft) |

| Pipe characteristics | 3LPP coated pipe and CWC pipe |