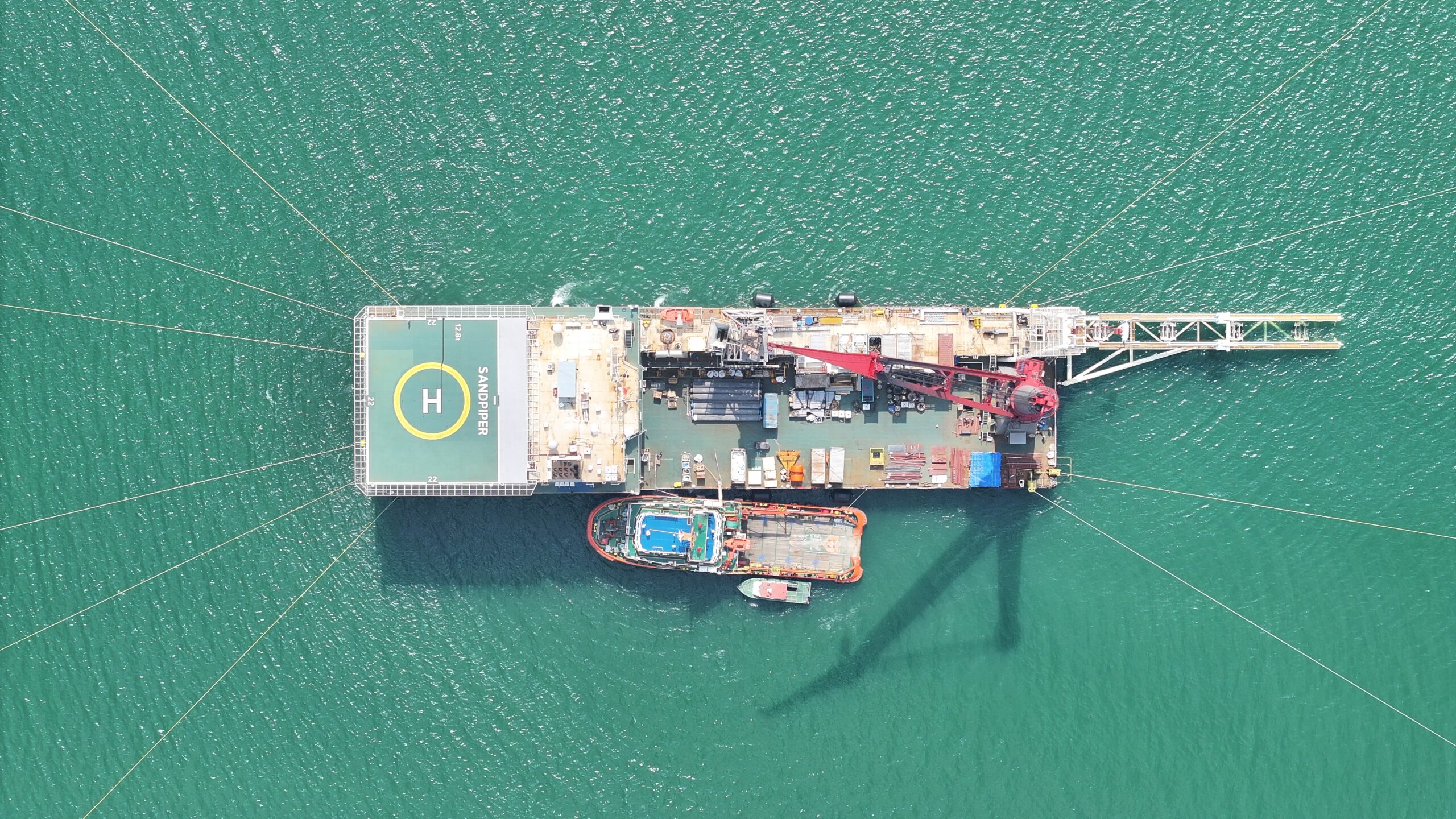

Sea trials Sandpiper completed

All systems are go on our newly converted shallow-water pipelay barge, Sandpiper, following successful sea trials off Johor, Malaysia. Crew are now mobilising the flat-bottomed barge for its first commercial project which kicks off next month. It caps an intense 18-months, during which the vessel was transformed from idle barge to Allseas’ gold pipelay standard.

A team of 25 engineers and 50 crew, supported by some 300 subcontractors participated in the upgrade design and engineering process to modify Sandpiper for a state-of-the-art S-lay spread. It’s the first vessel in the Allseas fleet fitted with an in-house developed automated anchor positioning system – designed to maximise safety and efficiency when operating its anchor mooring spreads in shallow waters.

Daniel Maron Blanco, Senior Naval Architect explains “The system replaces the old manual set-up where multiple operators control winches individually with joysticks. Now, a central console serves as the interface for the 10 winches. Enter a setpoint and the software does the rest. It speeds up positioning operations and eliminates operator errors.”

The overhaul included structural strengthening in certain areas, most notably upgrading the original stinger with a new design that allows us to continue laying pipe in extremer sea states. The updated firing line includes the latest version of our Phoenix automated welding equipment, and will include our phased array ultrasonic testing technology, Dolphin, and automated field joint sheet wrapping machine. All examples of what Allseas is doing to develop a safer, faster and more reliable production flow.

During pipelay trials, crew load-tested the A&R system and tensioners, followed by integrated tests: welding a string of pipe, performing a few pipe pulls and studying how the positioning system behaved together with the firing line and pipe string interface.