Phoenix

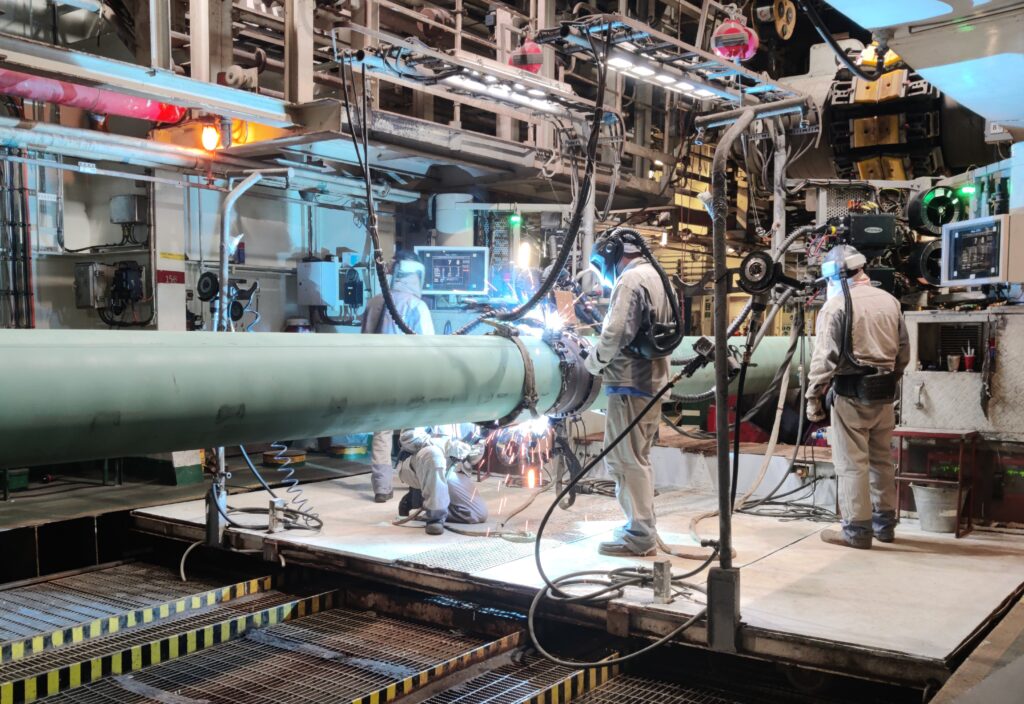

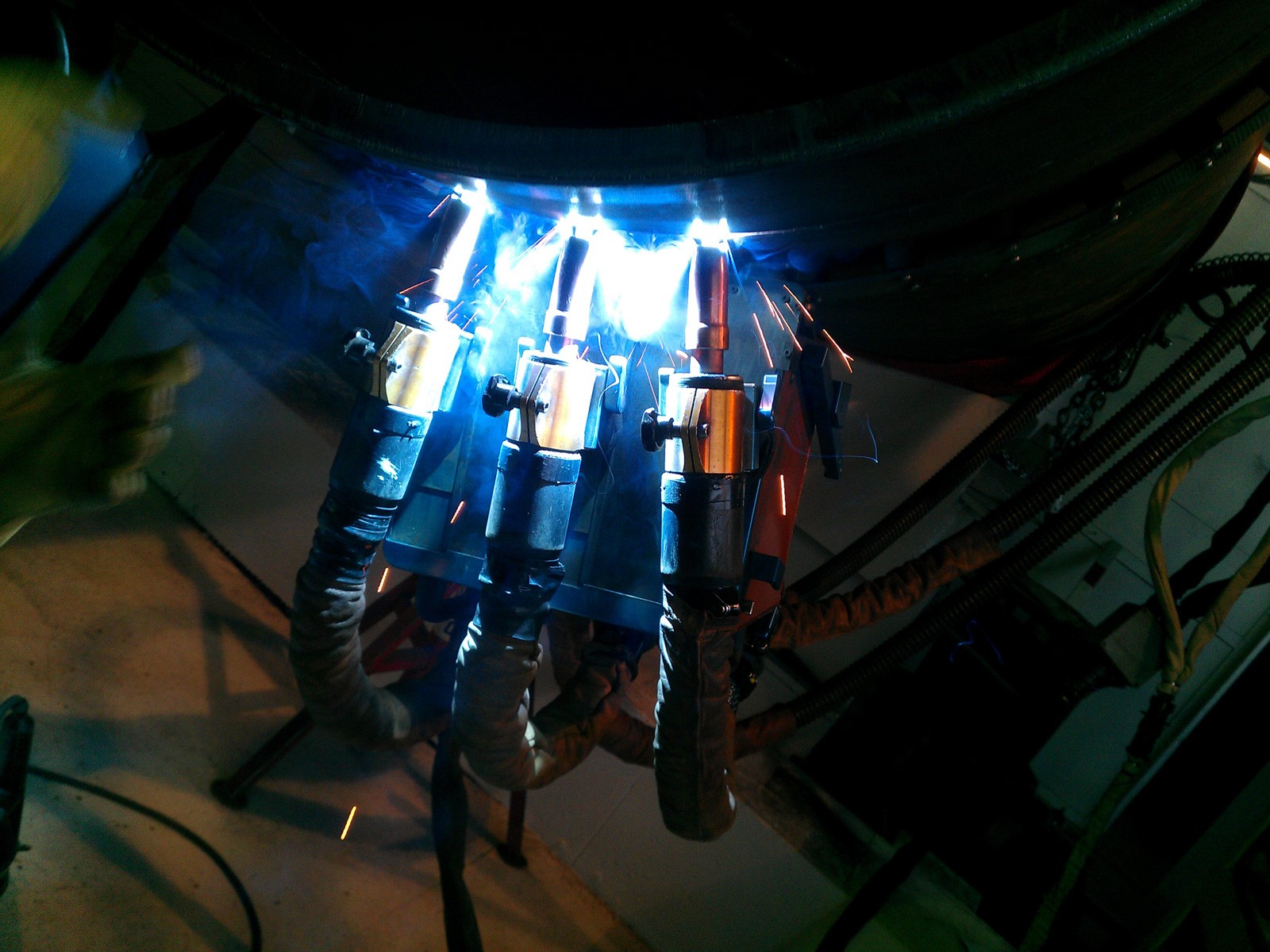

Allseas automated welding system, Phoenix, consistently produces high quality welds to meet the ever-increasing requirements of the oil and gas industry with respect to weld strength overmatching, corrosion properties, impact toughness and fatigue performance for the most complex and heavy wall pipelines. Allseas developed the concept in 1991, seeking to improve pipeline welding technology with the aim to provide assured quality of each and every pipeline weld. The system includes automated seam tracking and height control, which is paramount to proper position weld puddle in narrow groove welds. Welding parameter can be set for each clock position, and locked during production to ensure welding within qualified parameter ranges.

Phoenix – which has welded over 26,000 km of pipelines since its introduction in 1993 – has undergone several advancements including dual torch and triple torch arrangements, further optimising the system and increasing the weld speed on large diameter pipes. All the detailed engineering and development of the hardware and software is performed in-house, as is as the manufacturing of the system itself. In this way, Allseas maintains full control over maintenance and project-specific modifications. Besides the obvious welding of carbon steel for all available high strength grades, Phoenix has been used to weld lined and welded stainless and Inconel clad steel, stainless steel (Super)Duplex/316, and 13%Cr materials, using combinations of the processes available.

To enable root welding without copper backing, the Phoenix welding system has also been integrated with closed and open root welding processes.

Dolphin AUT system

Dolphin is an automated ultrasonic weld testing system that boasts the next generation of image-based inspection techniques called Virtual Source – Total Focusing Method (VS-TFM) for inspection of pipeline weld. Ultrasonic TFM images generated from multiple virtual sources merge in real-time to present volumetric weld data as detailed on screen 3D images.

Weld inspection takes place directly after finalisation of the girth weld using a lightweight scanner fitted to our in-house welding band. Ultrasonic signals are collected – using two-phased array probes and ToFD probes –digitised close to the scanner in an E-trolley and sent via fiber optic to the operator PC. The weld is displayed in a live feed in top view, side view and cross section view, together with complementary ToFD images.

Thanks to the combination of detailed views, the AUT operator can identify weld flaws at a glance by shape, location, orientation and defect characterisation. A set of simplified and clear sizing rules, supplemented by unique software tools immediately determine acceptance or rejection of the weld flaw against project acceptance criteria. After sentencing of the weld, a report is automatically generated and entered into the reporting system, completing a full digital record of the completed pipeline.

Dolphin made its commercial debut while we executed the pipeline installation scope for Petrogas E&P Netherlands’ Stage 2+ project in the Dutch North Sea.

Internal welding inspection tool

Originally developed for Allseas’ pipelay scope on the Gorgon Jansz project, our internal welding inspection tool (IWIT) extends and enhances the interpretation capabilities of the quality control inspector. Based on lessons learnt from all applicable projects and new technical insights, the Allseas IWIT has grown to a very robust and reliable internal measurement tool. Equipped with a colour camera and laser surface profiler, the tool takes visual weld inspection to the next level with pin-point accuracy. The camera captures welding related indications, misalignment, and weld penetration. Using the high quality images that appear on the computer screen, the inspector can examine the colour appearance stainless steel welds and the condition of the surface.

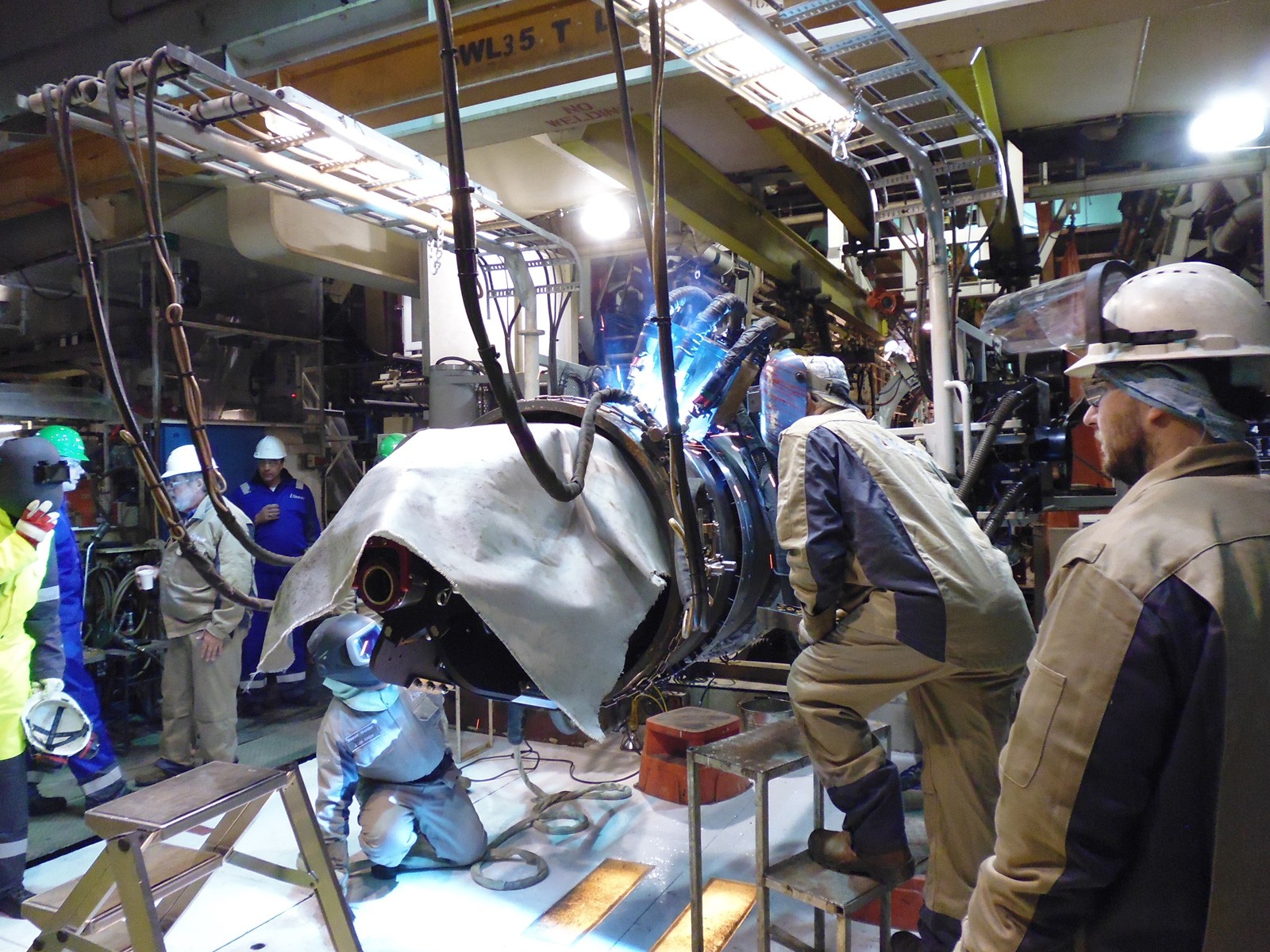

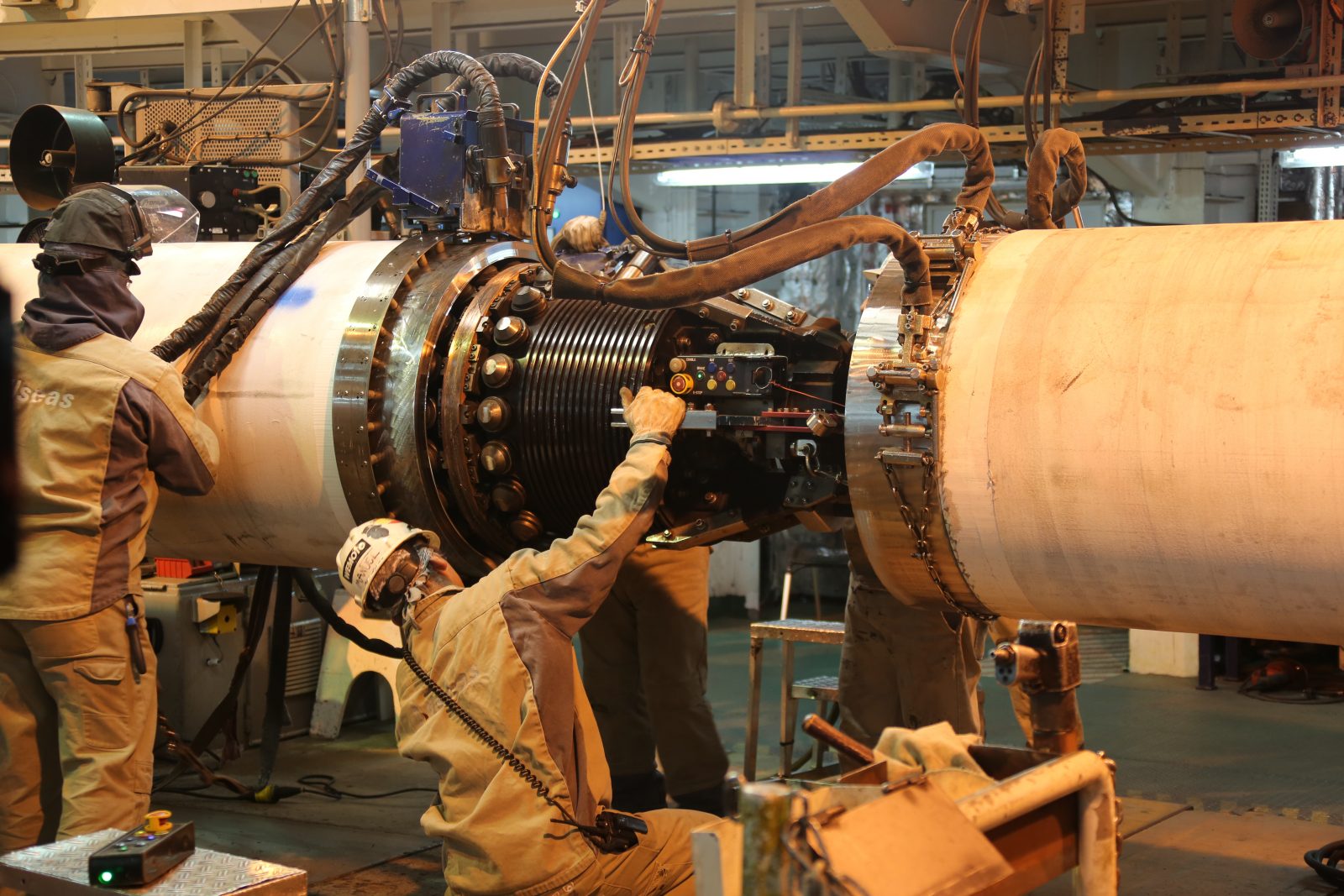

Internal line-up clamp

The Allseas internal line-up clamp is an in-house designed hydraulic clamp with the purpose to reduce the global out of roundness of the pipe and reduce the required line-up time. The clamp fits two pipe sections together after they have been lined up. Uniquely, the clamp's hydraulic pressure can be regulated, and is substantial enough to alter the shape of the pipe end to optimise its circular shape. The maximum force per stamp can be set up to several tonnes so it can also be used for pipelines with heavy wall thicknesses. The reduced out of roundness of the pipe improves the quality of the weld and line-up process, thus ensures fewer weld repairs. For stainless steel cladded pipe welding, the Allseas clamp is outfitted with purging capabilities to meet the welding requirements with inert gas-backed roots.

Learn more about Alleas' activities, projects and equipment.